As part of an investment program, projects aimed at upgrading of mining machinery, equipment, production modernization, improving of labour conditions, workers' amenities, safety level and mitigating of environmental impact were implemented at Northern, Central, Ingulets and Southern GOKs, Metinvest plant - Kryvyi Rih Machining and Repair Plant (KRMZ).

One of the largest projects in the history of Metinvest Group and mining industry of Ukraine implemented in 2021 was putting crusher and conveyor lines into operation at Northern and Ingulets mining and beneficiation enterprises. Investments into these two projects amounted to US 250 million. Operation of the new facilities will allow to increase productivity, reduce energy costs and mitigate environmental impact. Thanks to modern technologies, Metinvest positions at the iron ore global markets will be improved.

Mining and beneficiation enterprises have successfully implemented the investment program aimed at the equipment modernization and machinery upgrade. 12-cube excavators were purchased for Northern, Ingulets and Central GOK open-pit mines, bulldozer fleets of Northern and Central GOK were replenished. EPIROC drilling rings for pre-splitting were purchased for drilling areas of the enterprises, and seven BelAZ 130 t. vehicles were purchased for mining transport shop of Central GOK. 20 modern all-terrain buses with high mobility were purchased for safe and comfortable transportation of employees to vehicle shops of Central, Ingulets and Northern GOKs.

A number equipment modernization projects were implemented in order to improve quality and increase volume of finished products. A major overhaul of process section No.23 at Ore Beneficiation Plant No. 1 of Northern GOK was completed. In parallel with the main equipment replacement, the project for this section automation was implemented.

The new crushers - of fine, medium and course crushing - were installed for stable operation of Ingulets GOK crushing plant. Pumping equipment and drum separator upgrade works were performed at ore beneficiation plants of the GOK. In addition, implementation of the project for slurry pumping station No. 4 construction at the tailing storage phase 1 was continued and design works for phase 3 construction were accomplished in the previous year.

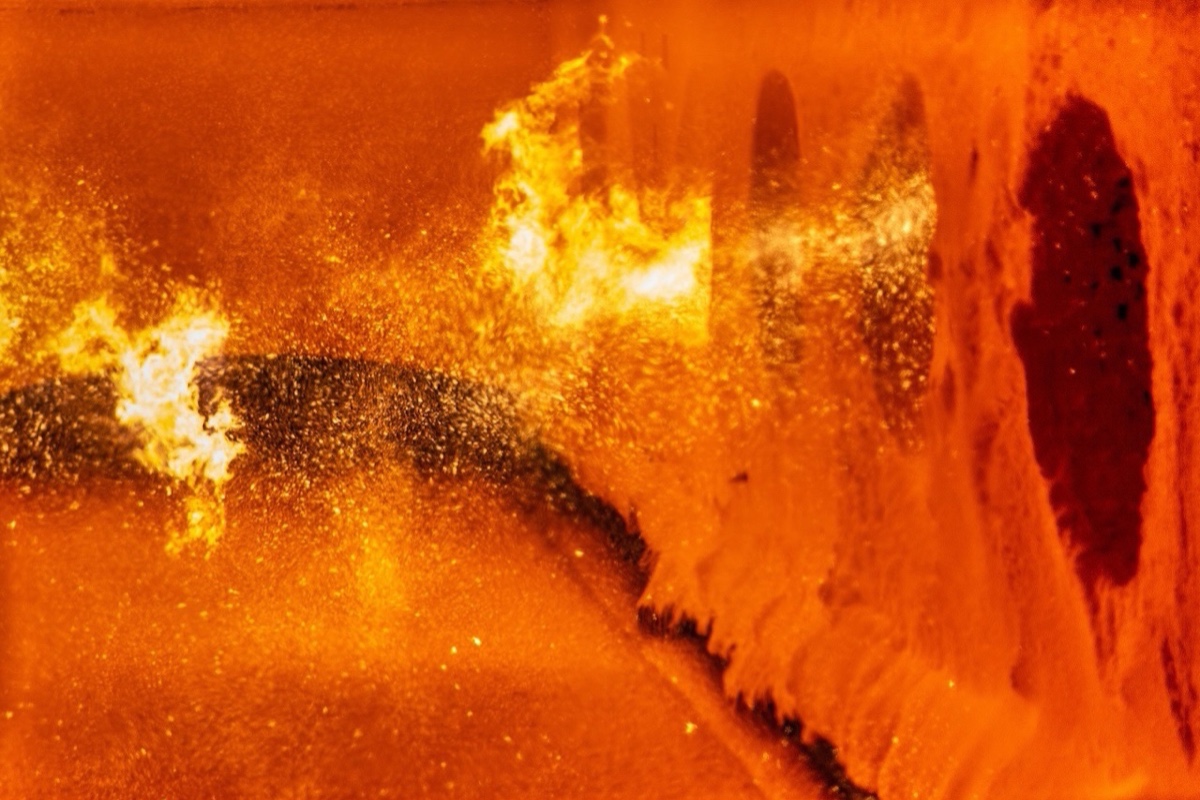

Roasting machine ОК-324 capital repair was carried out at pelletizing plant of Central GOK. As part of the investment project, 1,400 m2 of conveyor belt, classification equipment rollers were replaced, 100 t of refractory brickwork were revamped. A number of activities were performed to improve energy efficiency in the roasting area: pellet drying, roasting and cooling processes were upgraded, gas duct was replaced, new motors at smoke exhaust fan and flue were installed.

A large energy saving project involving frequency converters was implemented at Kryvyi Rih Machining and Repair Plant. The modern equipment allowed to save 35 % of electricity. 25 welding machines were purchased as part of Metinvest-KRMZ investment program. Works on capital repair of buildings and structures, roofing and glazing are in progress at the plant.

The main volume of the investments for Southern GOK was allocated to reconstruction of beneficiation equipment and purchase of mining machinery. Renovation of two process sections No.No. 9, 10 was finished at the first ore beneficiation plant. New ball mills, magnetic separators, deslimers were installed, foundations and process platforms were replaced as part of the investment program. Steel structures, water supply, heating and aspiration systems were revamped. As the result of the equipment modernization, the Southern GOK increased iron ore concentrate production volume by 5.5% versus 2020 - to 13.5 mln. t.

Let us recall that Metinvest Group is one of the largest investors in Ukraine's economy. The total amount of investments reached US 10 bln. in 15 years of the company totalling almost 80% of all the capital investments in Ukraine's economy during the same time period.