Since 24 February 2022, many Ukrainian businesses have been reflecting on their contribution to countering the aggressor. Metinvest Group, one of the largest businesses in Ukraine, combined the purchase of equipment, construction of defence structures and volunteering with the production of steel products. As part of Rinat Akhmetov's Steel Front initiative, the Group has become the largest private donor to the army and has put steel into service for the Armed Forces of Ukraine.

This story is about the transformation of Metinvest’s defence production during the war, the obstacles to its development and challenges that need to be overcome to form a powerful Ukrainian military-industrial complex.

Stage 1. Personal armour

The production of steel products for the Armed Forces of Ukraine started at the beginning of the invasion in 2022. The Group quickly focused on the immediate needs of the army, starting with the production of plates for bulletproof vests, which at the time were the most in short supply at the front. The plates were supplied to bulletproof vest manufacturers across the country free of charge. Later, the Group mastered the full cycle of production of the highest protection class of bulletproof vest and supplied around 150,000 units to the armed forces, that is, one for every tenth soldier in the army.

In the first months of the war, the production of small steel products for the army was put on an assembly line. Metinvest’s steel was used to make more than 80,000 anti-tank hedgehogs and spikes for wheeled vehicles, over 5,000 field stoves, and 256,000 staples for the construction of defences.

As the hostilities progressed, the needs of the military changed: in addition to bulletproof vests, the Group introduced the production of armour protection for frontline vehicles, which was provided for 310 vehicles.

With the proliferation of kamikaze drones at the front, engineers developed “lancet catchers”, 61 of which are already protecting military equipment.

As the war progressed, the needs of the military inspired the Group to expand its product line for the front, and production itself became more technologically advanced. In particular, in 2023, Metinvest began manufacturing mine trawls for tanks − 19 trawls are already in operation at the front. The requests of the military were becoming more complex.

Stage 2: Large underground structures

One of the biggest issues in building the defences was the speed of deployment. Thousands of kilometres of the front line required new defensive lines in a short time. Metinvest then began to produce underground bunkers made of corrugated steel. The first “hideouts”, designed according to advanced Soviet blueprints, were supplied to the front in the summer 2022. Currently, the army has received 559 bunkers.

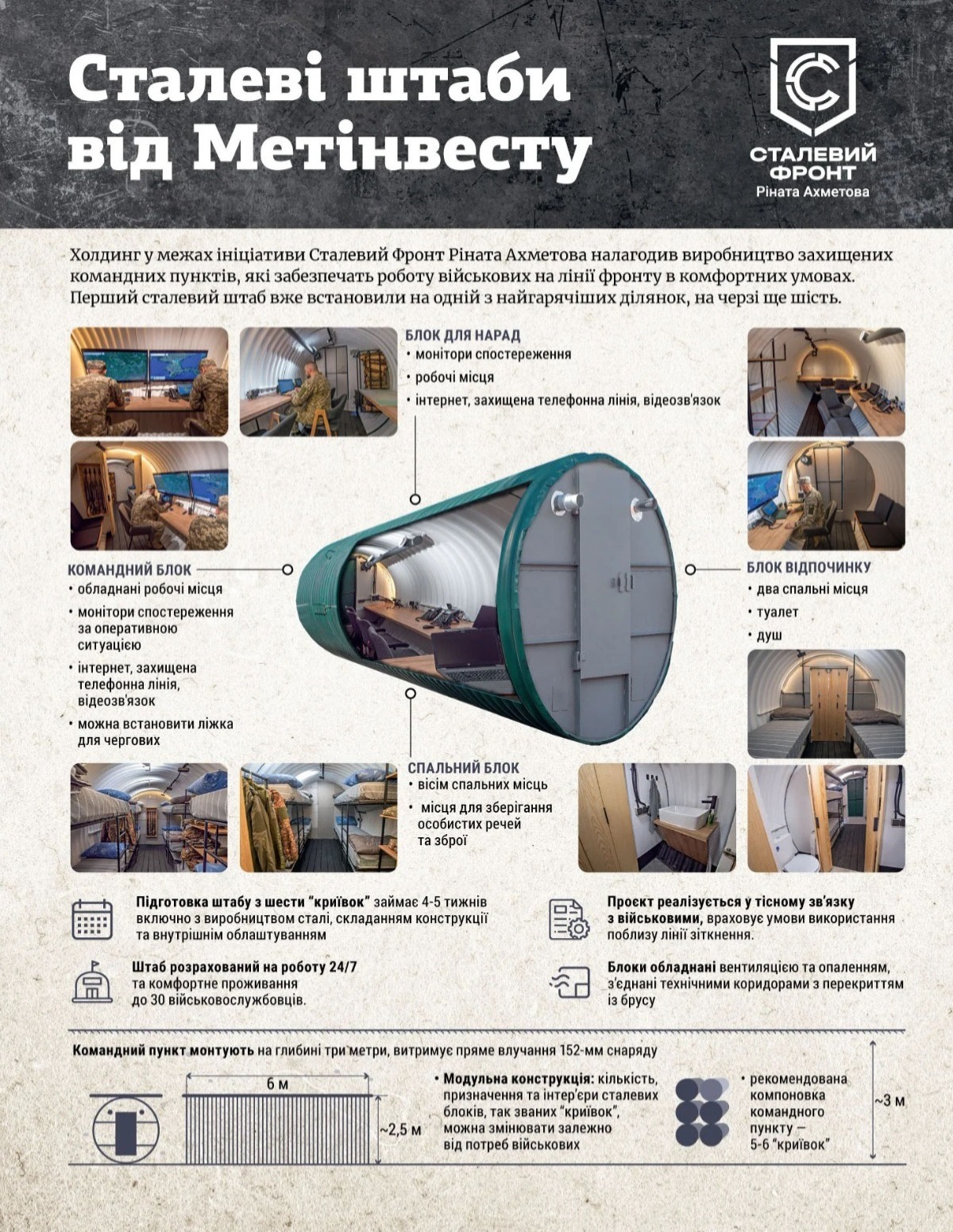

Later, the Group received a request for command posts to manage military operations on the zero line. Metinvest engineers developed a new configuration of steel shelters. The first “decision-making centre” for 30 soldiers has already been installed in one of the hottest areas of the front line.

Oleksandr MYRONЕNKO, Chief Operating Officer of Metinvest, said: “The main purpose of these posts is to continuously manage the troops in a protected environment. Some incoherent actions begin on the front line without coordination. These stations are very much needed now, and we continue to produce them.”

The steel headquarters consists of five to six interconnected mobile shelters that perform various functions, from living quarters to operational units. They can be quickly deployed and dismantled, protecting against artillery fire when properly installed three to four metres underground. Each bunker can accommodate six people and is equipped with everything needed for a comfortable stay and work.

It takes four to five weeks to manufacture one structure. Metinvest is planning to produce around 30 command posts and is also developing “hideouts” for drone operators and stabilisation medical stations. The Group promises to provide more details later.

Stage 3. Increasing production

Up to 500 Metinvest employees are involved in the production of defence products, making hideouts, trawls or bulletproof vests in their spare time.

Metinvest is assured that it can increase production of such products, but there are several issues that limit the Group’s capabilities.

First, there is a lack of people. Employees involved in defence are taken away from the production of steel, semi-finished products and raw materials. It is the main production that makes it possible to provide for the army and pay taxes, which also work towards the country’s victory. It has become difficult to hire new people due to migration, mobilisation, draft deferral issues and other factors.

Second, the Group believes that the involvement of private companies in the production of products for the front will accelerate the development of the military-industrial complex. A government order for steel products for defence could stimulate the opening of new workshops, create workplaces, and provide the army with the products it needs.

Myronenko added: “Yes, we are capable of increasing production volumes. We have the facilities and equipment – we need people who will focus solely on military orders.”

Only by overcoming these challenges will Ukraine be able to set up the production of defence structures, reduce its dependence on external assistance and strengthen its defence capabilities, which are an important component of victory.