During a scheduled three-day shutdown, Northern GOK employees completed planned maintenance at the ore beneficiation plants (RZF-1, 2) and slurry pumping station No.1 (SPS-1). All upgraded equipment was successfully recommissioned on schedule.

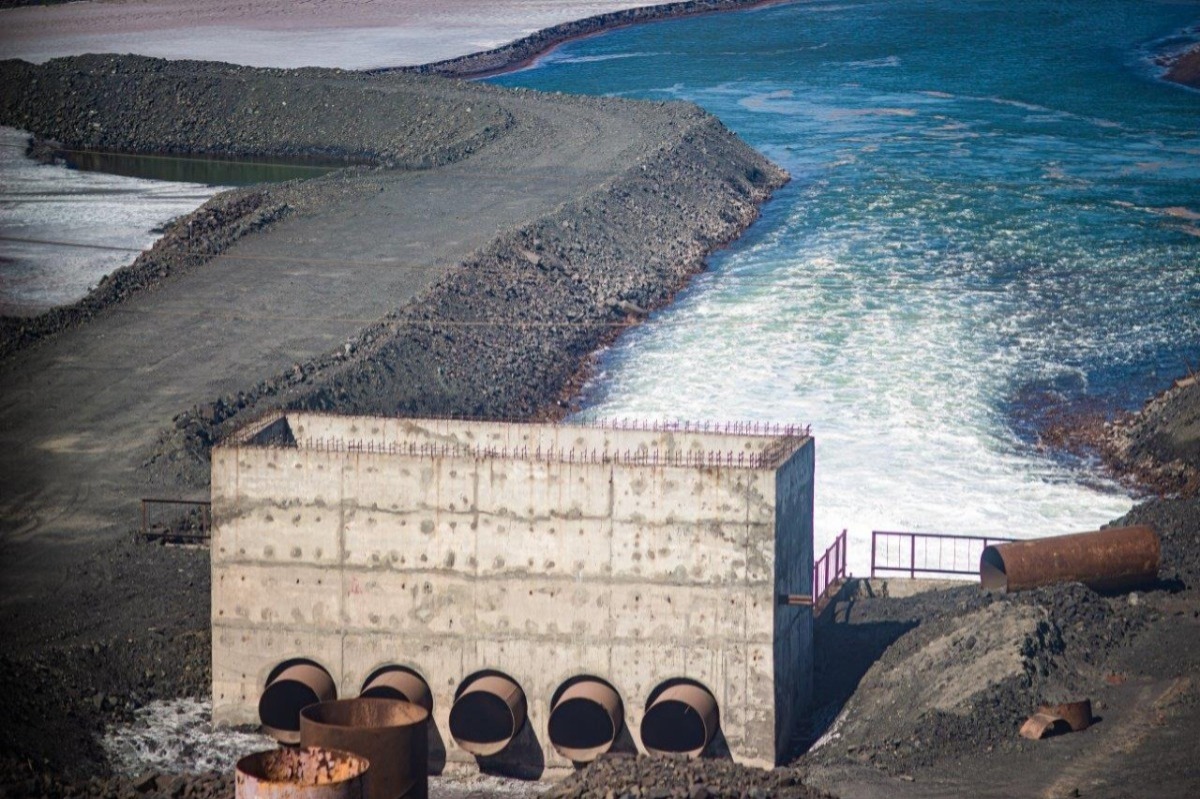

The maintenance work began with shutting down the slurry pumping station of the water supply facility and sludge processing department. The maintenance scope included replacement, repairs, inspection, and technical servicing of pumping equipment, valves, and water supply pipelines.

"Our primary objective was to optimize the technical water supply system. We focused particularly on the equipment critical to this process. The replacement of this equipment is only possible if the processing complex is stopped, specifically the RZF-1, 2, and SPS-1 divisions. Our technical team conducted preliminary equipment diagnostics to identify components requiring replacement. To ensure efficient operation of the equipment, we have planned the necessary repairs to avoid emergency downtime in the future," explained Dmytro GORILSKY, head of the GOK's Engineering Directorate.

The most important stage of the repairs for the RZF-1 was the replacement of two valves for pipeline fittings used to shut-off water flow in the mains.

"These valves had already served their useful life, so they were dismantled, and new ones were installed - smaller and more modern and functional. At the same time, we installed new valves in six process sections. This is necessary to ensure that the water supply to them can be cut off in the case of planned or unscheduled shutdowns," commented Olexander GOLOVKO, Deputy Head of RZF-1 for Engineering.

The RZF-2 team also executed significant upgrades during the shutdown. They replaced the pipeline and the valve of water supply line No. 7, as well as sections of the pipeline leading to the vacuum filters, the hydraulic discharge pipeline, six-jet slurry separator valves, and pumping section valves. According to Igor Vladeshchikov, head of Northern GOK's second ore beneficiation plant, this set of work will ensure the stable operation of the plant for a year until the next planned shutdown.

The specialists also repaired units and equipment at slurry pumping station No.1. Nine bottom valves and a rotary gate valve at the stationary pumping station were replaced, and the water supply system was restored.

All facilities resumed normal operations on schedule following the three-day maintenance period.