Kennedy once said that one should not ask what the country has done for you, but rather what you can do for it. Metallurgy is not something abstract. It can be seen and touched. Ships, bridges, building, and many more are made of steel. Metinvest has tens of thousands of metallurgists and miners. We live and work in Ukraine and for Ukraine. It is both simple and significant at the same time. Read our new article about objects created from Ukrainian steel.

"HETMAN IVAN MAZEPA" CORVETTE

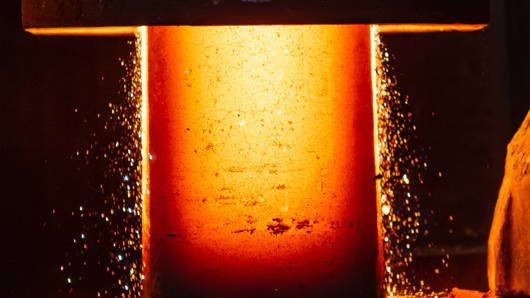

Usually, ships become legends after voyages and achievements. However, "Hetman Ivan Mazepa" became famous before its launch. The first Ada-class corvette and the future of the Ukrainian Navy, it was made of unique material – steel from Illich Steel and Iron Works and Azovstal.

One thousand tonnes of hot-rolled steel sheets and plates were turned into a modern flagship almost 100 metres long. The corvette was built using stealth technology and is equipped with radar and sonar systems, a hangar for a helicopter, and a flight deck.

The "Hetman Ivan Mazepa" first went to sea in October 2022. In May 2024, the corvette began its sea trails with a 76-mm artillery mount, a 35-mm anti-aircraft gun, and remotely controlled STAMP system.

The work of metallurgists from Mariupol marked the first step in Ukraine's path towards a strong and modern fleet. Their steel continues to contribute to victory even years after the destruction of Illich Steel and Iron Works and Azovstal.

CHERNIHIV BRIDGE

Metinvest's steel is the cornerstone of Ukraine's reconstruction. At the beginning of the full-scale invasion, the occupiers destroyed the Chernihiv Bridge, but its reconstruction began in autumn 2022.

Yevhen Paton would have envied the pace of work. The first section of the bridge reopened in May 2024. To stay ahead of schedule, bridge builders worked around the clock in two shifts of 1,000 people each. Not even the largest floods in 130 years, which inundated the construction site, brought work to a halt.

In October 2023, the bridge complex entered the Book of Records of Ukraine for the longest monolithic span structure. At more than 122 metres long, it took specialists almost two days of uninterrupted work to pour the concrete.

Symbolically, among the 3,200 tonnes of steel that Metinvest-SMC promptly supplied to the builders was metal from Azovstal. Despite the tragic loss of the enterprise, its products now support one of Ukraine's most beautiful bridges.

At 628 metres in length, with a modern design and pedestrian and cycle paths, the structure is built to last at least 100 years and has already become a new architectural landmark of the Chernihiv region.

MAIN WATER PIPELINE

Water is life. Metinvest helps to deliver it to where it is needed most. In March 2025, construction began in the Mykolaiv region on a new 67.8-kilometre main water pipeline.

Based on calculation, the project needs approximately 500 tonnes of steel products which Metinvest will supply. The project requires around 500 tonnes of steel products supplied by Metinvest-SMC, mainly pipes with a diameter of 800 to 900 mm. Able to withstand pressures of up to 16 atmospheres and resistant to temperature fluctuations and chemical exposure, they will reliably serve residents for many years.

According to the plan, the work will take around five months – an exceptionally short period for a project of this scale. To finish on time, more than a thousand specialists and hundreds of units of modern equipment are working on site around the clock. The launch of the main water pipeline is scheduled for August 2025, meaning that within a few months the people of Mykolaiv will gain access to high-quality drinking water.

A SUNNY MEMORY OF AZOVSTAL

From Troieshchyna to Darnytsia in just 15 minutes. Cheerful yellow, comfortable and modern, trams made from Azovstal’s steel have become a true adornment of the capital’s streets. Equipped with two-stage suspension and ramps, warm in winter and cool in summer, they entered service in spring 2023 and have been bringing Kyiv residents joy ever since.

Interestingly, all eight new trams have Ukrainian "passports", as they were produced in the Tatra-Yug shops. To manufacture them, 17 tonnes of cold-rolled and 98 tonnes of hot-rolled steel sheets and plates, supplied by Mariupol’s metallurgists before the war, were required.

In this way, the steel of the legendary plant continues to serve Ukrainians – in solid buildings, reliable bridges, and comfortable public transport.

"WAVES" ON THE DNIPRO RIVER

Three hundred tonnes of complex steel structures. Futuristic design and strength come together in a single construction that unites the banks of the capital. Yes, it is another bridge – but a special one. It was built from the last steel produced by Azovstal, manufactured just before the full-scale war began.

The construction lasted nearly five years: work that began in 2020 was halted by the war, but thanks to Ukrainian and international sponsors, it resumed, and in May 2024 Kyiv residents finally set foot on the long-awaited wave-shaped bridge.

Four metres wide and 164 metres long, the structure connects Obolon Island and Natalka Park. Built with people in mind, it was designed in full compliance with accessibility standards for people with limited mobility. Thanks to Azovstal’s steel, shortly after opening the bridge also became a new symbol of Ukrainian resilience.

"SHELTER-2" PROJECT

Amidst Ukraine’s blossoming spring, there is a ghost territory. Access is prohibited, the streets are deserted, and life as we know it has long since disappeared. This place is Chornobyl.

On 26 April 1986, the largest accident in the history of nuclear energy occurred. First protective sarcophagus over the fourth reactor was built in a record 206 days. From the outset it was clear that this was only a temporary structure, expected to last around 30 years. The danger of Chornobyl extended far beyond Ukraine.

In 1997, the G7 countries decided to create a fund to finance the construction of a new protective structure, "Shelter-2." By 2004, the project already had 40 donor countries. Installation of the second sarcophagus began in 2012. More than just ordinary steel was required to build it. Metallurgists from Mariupol worked to produce the specialised metal. It was a challenging task. One indicator – the impact toughness of the rolled sheet and plate – exceeded standard requirements by two to three times. As a result, Metinvest supplied almost 2,000 tonnes of sheets and plates from Azovstal. Additionally, Metinvest Trametal delivered a further 13,300 tonnes to the special contractor named Novarka, part of the Italian construction company CIMOLAI.

The new insulating structure, worth EUR 1.5 billion, took 9 years to build. The "New Safe Confinement", as the arch was officially called, became the largest movable land-based structure in the world. Its dimensions: 165 metres long, 260 metres wide, and 110 metres high. Both the Statue of Liberty and London’s Big Ben could easily fit inside. And with the amount of steel used for the shelter, it would have been possible to build three Eiffel Towers.

On 29 November 2016, the sarcophagus completely covered the original shelter. The structure will contain radioactive emissions for the next 100 years.

KYIV OLYMPIC STADIUM

The National Sports Complex "Olimpiyskiy" is a sporting arena for football matches, athletics competitions, cultural events, and other large-scale events. It was built in 1923. The stadium is the largest in Ukraine and the second largest in Eastern Europe by capacity. Its total area is 145,741 square metres, and it can accommodate 70,050 spectators.

Kyiv Olympic Stadium has repeatedly become the centre of major sporting and cultural events. During the 1980 Summer Olympic Games, six group-stage matches and one quarter-final were held here. As part of the UEFA Euro 2012 championship, co-hosted by Ukraine and Poland, the stadium staged three group matches, one quarter-final, and the final.

The stadium has also hosted the "Tavria Games" festival, as well as concerts by Madonna, George Michael, Shakira, Red Hot Chili Peppers, Kasabian, Depeche Mode, and Okean Elzy. Over the years, the venue has undergone several renovations, with changes to its layout and capacity. Metinvest supplied hot-rolled sheet for 7,500 tonnes of steel structures used in the stadium’s modernisation ahead of Euro 2012. The reconstruction lasted 38 months, and following its reopening the football stadium of Kyiv Olympic Stadium was awarded UEFA's highest status.

LIODOHRAI

At Metinvest, we believe that every child should have the opportunity to grow fully and take part in sport. Many people are already familiar with our initiatives "City with Our Own Hands" and the Social Partnership Programme.

The Winter Sports Centre "Liodohrai" is another social project in which our products were used. In 2014, a very important event took place in the small town of Bohuslav: not just an ice arena appeared, but 2,560 square metres of winter joy, available all year round.

The multi-purpose training centre became home to hockey and figure skating schools, as well as gyms for fitness and choreography. The Ice Hockey Federation of Ukraine certified the arena as meeting federation standards, and since then it has hosted matches of the Ukrainian championship. Later, figure skating joined hockey as a permanent feature.

The complex was also built using environmentally friendly and energy-saving technologies. Its power unit does not rely on natural gas but runs on sunflower husks.

DARNYTSKYI BRIDGE

The story of the Darnytskyi Bridge began in 1868. Construction was swift, and by February 1870 a special test train consisting of six locomotives had already crossed it. The bridge stood on 11 pillars and had a single railway track.

The bridge was blown up three times: first by Polish forces in 1920, and again in 1943 during the retreat of German troops. Just 14 days later, a temporary low-water bridge was built next to the destroyed one, followed by a temporary high-water bridge in February 1944. In 1949, a new Darnytskyi railway bridge was opened with two tracks. After 50 years, however, it could no longer handle the growing load and required major reconstruction.

Construction of the new Darnytskyi rail-and-road bridge began in June 2004. Spanning the Dnipro River from the left to the right bank, it required the installation of 35 pillars, 13,600 tonnes of steel structures, and 31,200 square metres of special asphalt surfacing with a service life of 30 years.

Metinvest supplied 6,000 tonnes of steel plate for the project. The bridge is 1,066 metres long and includes two railway tracks, six traffic lanes, and two pedestrian walkways. Its capacity is 160 train pairs and 60,000 tonnes of vehicles per day.

RESIDENTIAL COMPLEXES

"PARKING CITY' IN THE BIG CITY

In 2014, the "Parking City" residential complex was recognised as the best housing development in Ukraine. Metinvest contributed to the construction by supplying 1,000 tonnes of rebar. The result was a true "city within a city" with its own infrastructure. Spread over 17 hectares in the Podil district of Kyiv, 8.5 hectares of the area are dedicated to parkland with cascading ponds and valuable tree species. Here lies the historic park "Kristerova Hirka." Few modern cities can boast so much greenery.

"PEARL" OF THE SOUTHERN PALMYRA

Using steel structures in construction makes it possible to build taller, larger, and uniquely shaped buildings. Such buildings are safe, reliable, spacious inside, and extremely strong. From the outside, they also look striking. A good example is the "Pearl" residential complex in Odesa, for which Metinvest supplied more than 2,000 tonnes of rolled steel for the construction of 21 residential buildings.

BRIDGE OVER THE SUKHYI ESTUARY

Drivers want speed and no pontoons. Maybe not all, but certainly most who often travel along the Odesa–Chornomorsk route. The problem is that the existing pontoon crossing over the Sukhyi Estuary was built 50 years ago. Vehicles over 20 tonnes are not allowed to use it, and every five years it requires major repairs.

Weighing the pros and cons, it was decided to build a new bridge. When something is said, it does not mean that it have been already done. However, the work pace is positive. In 2018, Metinvest-SMC delivered 520 tonnes of alloy steel of grade S355 and its analogue 09G2S to the south. This is the most popular steel grade in Ukraine, used to manufacture most high-strength rolled shapes. Additionally, steel of grade 15KhSND was supplied; in addition to its strength, it is resistant to corrosion.

Steel is a universal material from which objects of almost any form can be created.

THE GLASS BRIDGE

That very pedestrian bridge in the centre of Kyiv, connecting Volodymyrska Hill with Khreshchatyi Park. Yes, it is made of Ukrainian steel. Yes, ours – produced at Azovstal. Opened on Kyiv Day, the bridge has become another landmark of the capital.

Built 40 metres above the ground, the bridge has a winding shape and offers diverse views of European Square, Podil, the northern districts of the city, and Kyiv’s slopes. For lovers of beautiful panoramas, special viewing platforms were created, widening the bridge from 6 to 14 metres in places. The total length of the bridge is 220 metres. Its construction used 700 tonnes of steel plates ranging in thickness from 8 to 55 mm.

SHOPPING AND ENTERTAINMENT CENTRES

Opera or theatre. Today, it sounds lofty. But in the past, people went there not only to "touch the beautiful" but also to relax, hear the news, and meet acquaintances. Nowadays, shopping and entertainment centres serve many of the same purposes.

Take "Cosmopolite" in Kyiv, for example. It houses more than 120 clothing and footwear shops, supermarkets, perfume and cosmetics stores, appliance and sports outlets. Plus, there is an ice rink, bowling alley, cafés, restaurants, cinemas, and a children’s entertainment complex. And in all of this, there is a little bit of Metinvest. Around 1,800 tonnes of thick plate steel from Illich Steel and Iron Works were used in the construction of "Cosmopolite."

Our steel was also used in building "Lavina Mall" – one of the largest shopping and entertainment centres in Europe. The name matches the scale inside. Here you can find extreme rides, roller coasters, a virtual reality cinema, a musical fountain, and much more. The total floor area is 170,280 square metres. Metinvest supplied 3,600 tonnes of rebar, pipes, sections, and rolled sheets and plates for its construction.

CENTRAL DEPARTMENT STORE

Every city has a place that people call its heart. A place infused with the spirit of past generations, yet one that also reflects everything new and modern. For Kyiv, that place is undoubtedly Khreshchatyk. Chestnut trees, pigeons, the flow of cars and people. Some rush to work, others stroll and admire the beauty of the city. Everywhere you look – history. And an important part of it is the central department store.

The department store has witnessed many heroic and tragic events. If this elder could speak, it would probably be the chief storyteller not only of Khreshchatyk and Kyiv but of the whole of Ukraine. In November 2016, it reopened its doors to visitors. Metinvest supplied more than 2,000 tonnes of steel for the reconstruction of the building. The central department store, familiar to many generations, received a new lease of life. Its story continues.