Engineering specialists at Ingulets GOK have repaired the drilling rig's equipment. Now the serviceable and productive equipment is already in use for drilling wells in the Ingulets open pit.

Employees of Ingulets GOK started the new production year with a gradual increase in ore mining and concentrate production. In line with the intensification of manufacturing processes, the enterprise is carrying out major overhauls of machinery and equipment. In order to enhance the drilling unit's performance, the specialists of InGOK's engineering function carried out a number of necessary repairs of the Atlas Copco PV No. 28 drilling rig.

In particular, the high-pressure hose was replaced in the hydraulic system of the machine, which is essential for efficient control and driving of various equipment components. An important stage of the repair was the installation of a new water pump that supplies water, creates pressure, and cools the equipment during drilling.

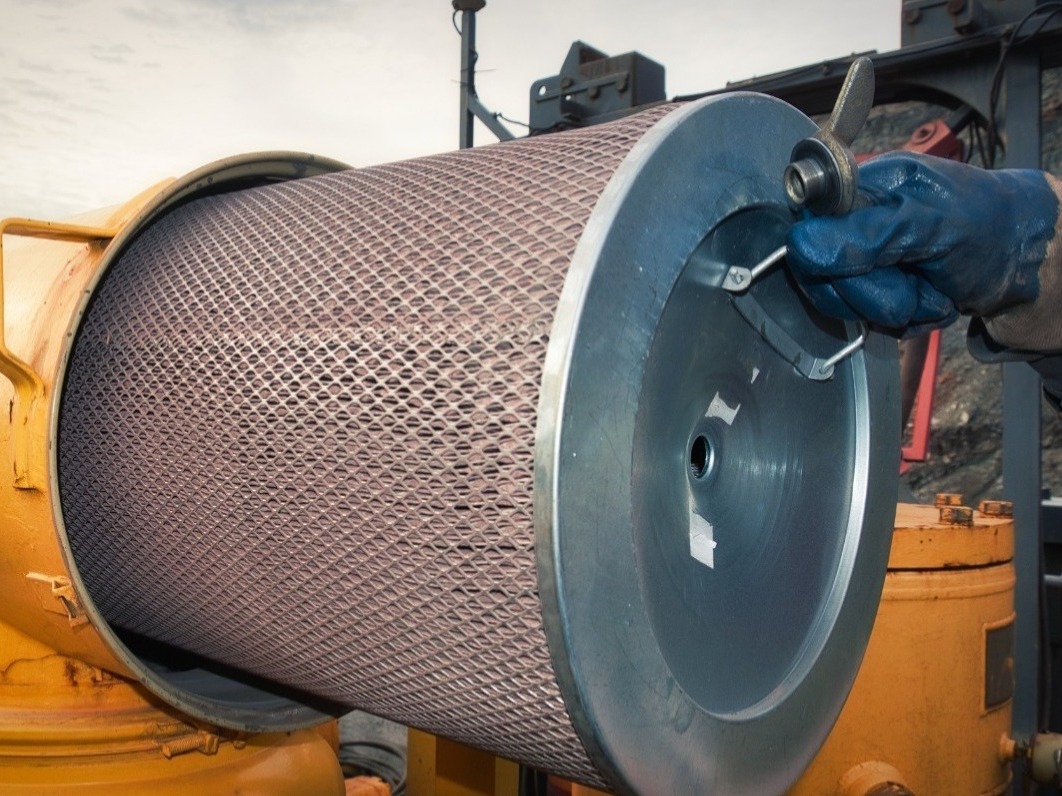

New hydraulic filters were also installed to protect the system from contamination and extend its service life. The replacement of the air filters will ensure clean and reliable operation of the compressor. The working conditions of the drilling rig's operator were also taken care of by replacing the filter in the cabin.

Now the repaired rig is back in service. It demonstrates high productivity - the well penetration rate is 9 metres per hour in the particularly hard rocks of the Ingulets field. The total depth of the wells drilled in the open pit reaches 30 metres. To date, 10 drilling rigs have been deployed at InGOK to successfully meet production targets.