A vacuum pump has been replaced in the dewatering area of ore beneficiation plant No 2. The new equipment will ensure the required moisture content in the iron ore concentrate. Metinvest allocated UAH 3.2 mln for this project.

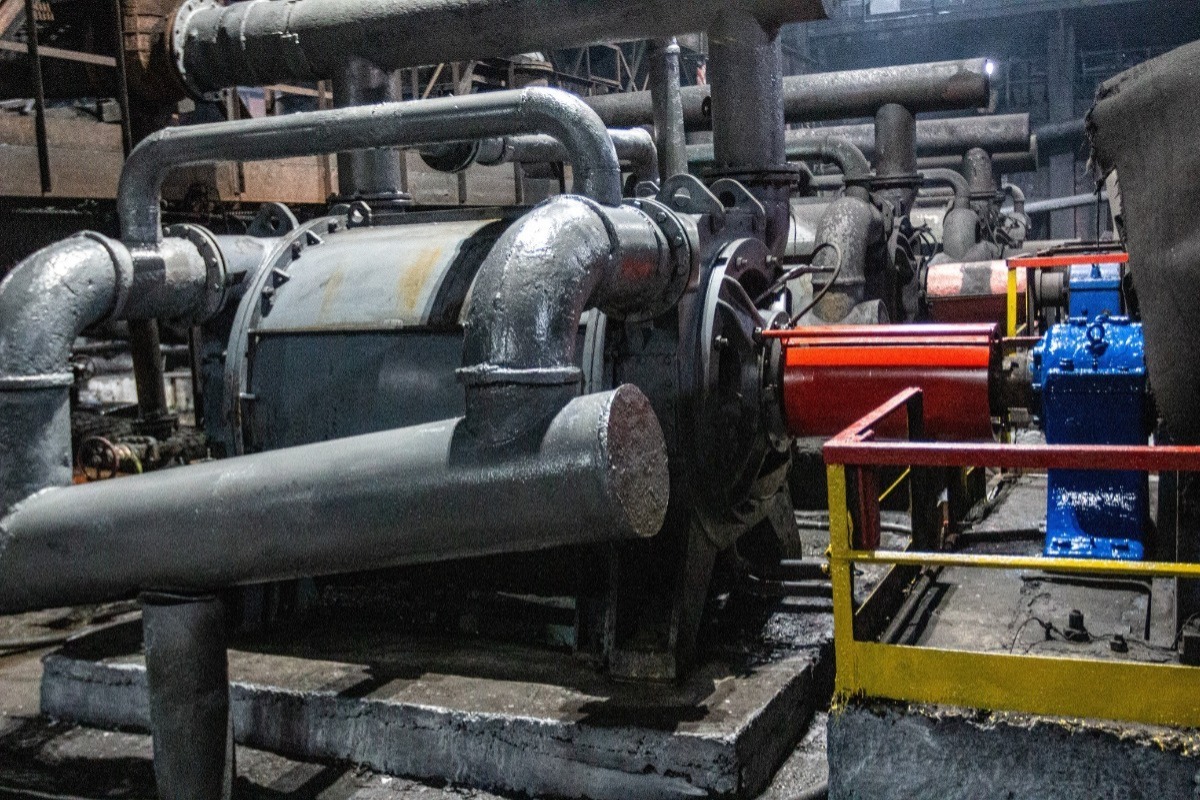

VNN2-300 vacuum pumps are used in the concentrate production process at the ore beneficiation plant No 2 (OBP-2). They are used to create a vacuum in the overall system when dewatering the concentrate. Overall, the plant has 18 units of such equipment, of which 17 are constantly involved in the process and one is a backup. As one of the vacuum pumps had worn out, the plant dismantled it and installed new similar equipment.

"The operation of a certain amount of pumping equipment directly affects the quality of the product, namely the percentage of moisture in the dehydrated product. A decrease in the vacuum in the header caused by the absence or malfunction of equipment leads to an increase in the percentage of moisture in the concentrate, which in turn requires an increase in bentonite consumption in the production of pellets in pellet shop № 2. The vacuum pump we replaced had effectively served throughout its expected lifetime - and then some. It was replaced by a new one of the same model type. It will ensure the nominal capacity and the required vacuum level in the system, enabling us to reduce the total number of vacuum pumps in operation in the process and reduce electricity consumption," Andriian MYSHKO, head of the ore beneficiation area of OBP-2, said.

In 2014, Northern Iron Ore Enrichment Works plans to replace two more units of pumping equipment at ore beneficiation plant № 2 with new ones.