In difficult conditions of power supply restrictions, Kamet Steel of Metinvest Group is implementing a programme of major overhauls of hot-blast stoves.

Difficult times for the country do not recede yet, but Ukrainian steelmakers work tirelessly in spite of the problems. Kamet Steel, even in conditions of power supply restrictions, keeps up with major repairs. The works on long-term overhaul of hot-blast stove No. 4 at BF No. 1M are resumed at the plant. The main objective is to replace the unit's refractory lining, which has become worn out in the course of operation.

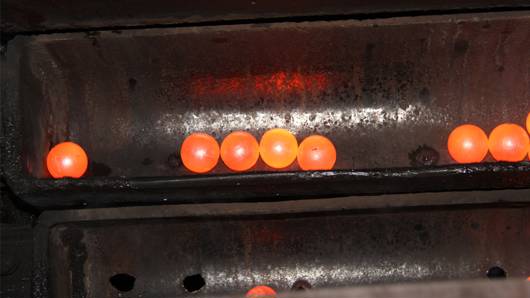

The repair specialists have already removed the defect lining of the combustion chamber, radial walls and dome of the stove, dismantled the checker-supporting grids and columns and installed new ones. The most important stage of the overhaul begins with the restoration of several thousand tons of refractory lining of the stove. The steel structures and working platforms will also be repaired. Also, as part of the overhaul, the partial replacement of cabling and wiring, the repair of control panels and lighting networks of the stove are planned.

– Effective blast heating is one of the most important steps in blast furnace production. Hot-blast stoves are important for saving fuel and increasing the productivity of the furnace. The overhaul of the stove will make it possible to increase the hot blast temperature, which in turn will reduce fuel consumption during smelting and increase the efficiency of the blast furnace," Yevgeniy PODGORNY, Deputy Head of the Blast Furnace Shop on Engineering said.

It should be recalled that overhauls of three hot-blast stoves at blast furnaces No. 1M and No. 9. were performed at Kamet Steel before the war.