New products under the 2025 programme are already a steel reality. In the first month of the new year, roller operators of Kamet-Steel successfully mastered the production of rebar products line in accordance with another Polish standard, B500SP.

It's worth reminding that last year, following the successful certification for compliance with Polish building regulations, the enterprise launched mass production of B500B rebar with a diameter of 8-32 mm for Polish customers. From now on, the enterprise will also supply rebar to the Polish market in accordance with the B500SP standard.

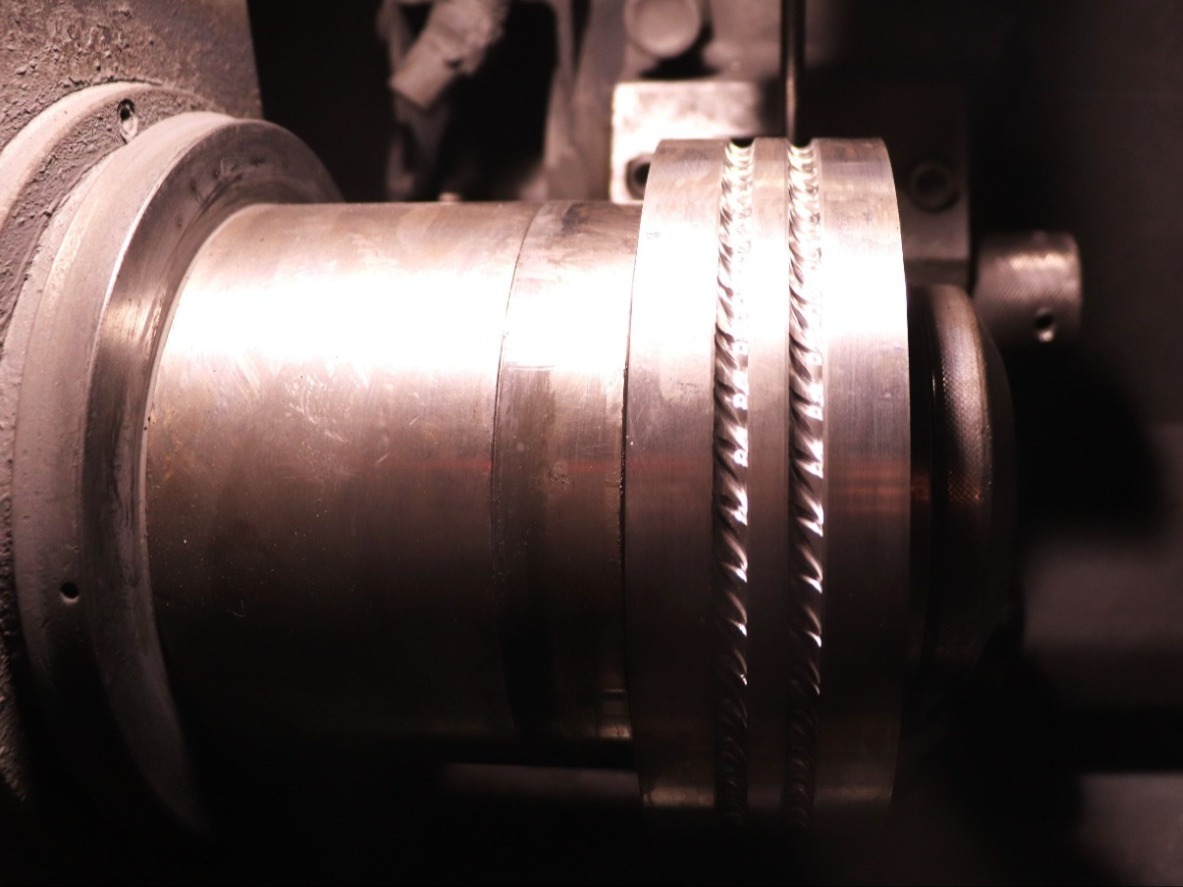

The specific requirements of this standard are not limited to geometric dimensions, linear metre weight and mechanical tests. Mastering and production of such products requires changes to the gauge pattern, the angle of reinforcement ribs cut, and other marking requirements.

A team of specialist technologists from the Rolling Mill Shop, rollshop area, calibration bureau and Technological Board joined forces to complete this important task. They developed technical solutions for the optimal production process, calibration tables, rolling patterns, performed rolls calibration, etc. The developed parameters were added to the software of the CNC machine tools used to prepare the rolls.

"Preparation of rolls for the production of B500SP reinforcing profiles has set new requirements for us. The technology for reinforcing grooves cutting has been completely changed: previously, it was cut at one angle and marked with rib gaps, while this standard requires cutting at two angles and marking with rib extension. To perform this work, a cutting tool of a different configuration is required, and the purchase of which, given the current difficulties, could have disrupted the terms of the sections' mastering. Therefore, the specialists of rolling department adapted cutting tools to the needs of product range being mastered on their own. We are also currently working on backup options to reduce the time required to manufacture such rolls", says Vitalii ROVKOV, Head of Rolling Mill Shop rollshop area.

In January, roller operators of 400/200 Rolling Mill mastered the production of five B500SP rebar sections with nominal cross-sections of 10, 12, 16, 20 and 32 mm. In February, they will continue to expand the product range for Polish market. It is planned to master production of rebar with a cross section of 8, 14 and 28 mm.

"Quick respond to market demands, expand of marginal products range and meeting the requirements of key European customers are the priority tasks for our subdivision. In January, we mastered and rolled over 1,200 tonnes of rebar to the new B500SP standard at the request of Polish customers and already have plans to implement the production programme for this product in-demand for the first quarter of 2025. We work as a single team with steelmakers who supply our orders for continuously cast billets with the chemical composition required to produce rebar for Polish customers. Along with the heat treatment modes optimally selected at 400/200 Rolling Mill, this allows us to ensure the required mechanical properties of finished rolled products in accordance with customers` requirements", says Roman LINCHENKO, Deputy Head of Rolling Mill Shop Section Rolling Mill area.